Were you ever curious about the making of whisky or what ingredients give it it's flavour? You could think of whisky as the sum of four ingredients mixed: artistry, care, patience and love. Whisky flavour distinct, and everyone's preferences are different. So, what are these arcane ingredients that go into the making of whisky? How do they contribute to Scotch's flavour profiles? Let's explain...

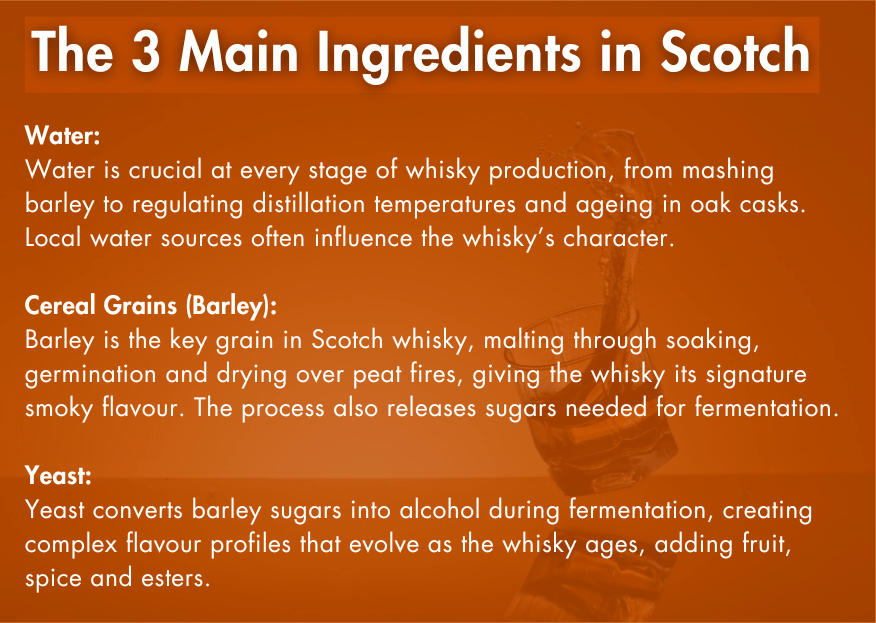

Three main ingredients that make Scotch whisky:

Water: Production is dependent on water quality. Certain elements, such as iron, can impact a particular character to the whisky. Distilleries almost always use local water sources.

Cereal Grains: Barley is the 'father grain' of Scotch whisky production. To malt the barley, it is first soaked in water long enough to germinate, usually for between three and five days. It is then dried in a kiln, usually over peat fires that help to both enhance the flavour of the malt wort and give the whisky a distinctive peaty flavour. Malt dries at a rate of ~1 per cent per hour in the kiln. During the drying process, the malt's starchy endosperm begins to liquefy, thereby activating enzymes. These are then used in converting the barley's starches into fermentable sugars during the fermentation process.

Yeast: Yeast takes the sugars derived from the malted barley and ferments it into alcohol. Different strains of yeast produce distinct flavour profiles in the final whisky.

Water

In the context of whisky, we cannot overstate the importance of water. The significance of water goes beyond brewing and distillation: water is an integral part of the drink. Influencing its character and quality at every stage of its production and consumption. Water is used in the mash to help release sugars from malted barley and, later, in the fermenters to help yeast break those sugars down into alcohol. In the stillroom, water sets the right temperature on the still and regulates the strength of the new-make spirit. Water also reacts with the wood in oak casks in which whisky is aged. This helps the spirit absorb a degree of flavour and aroma and gain degrees of smoothness and complexity along the way. Finally, a few drops of water in a tumbler or Glencairn glass will help to unravel a whisky's character, bringing it to life on the nose and palate.

The Grain – Barley

Barley sacred in the production of Scotch whisky; it is central to its production and to the flavours and character of the spirit. As the chief grain used in Scotch whisky production, barley is processed through a method of partial germination known as malting. Soaking, germination and drying are applied to activate critical enzymes. Sugars are then produced that will ferment to make the spirit. The variety of barley used in distillation will have significant effects on the end product. Peat smoke exposure, for one, will give the whisky an earthy and smoky aroma and taste. From Scotland's fields to its distilleries' copper pot stills, barley in Scotch whisky elevates it to a pinnacle of craftsmanship and experience in the arts.

The Role of Yeast

Whisky production relies on yeast; it is essential for the process. It's the addition of the fermenting microorganism that wakes up the sugary liquid and sparks the alchemy of the science. As live yeast converts the sugars extracted from malted barley into alcohol and carbon dioxide, the fermentation vessel crackles into life. Yeast fermentation converts runny, sugary wort into a low-alcohol liquid called wash. The thousands of compounds in whisky acquire flavours from fruit, esters and spice. Yeast infuses the spirit's taste, and as it evolves in body, colour and strength with age, it is responsible for the outcomes of taste and flavour.

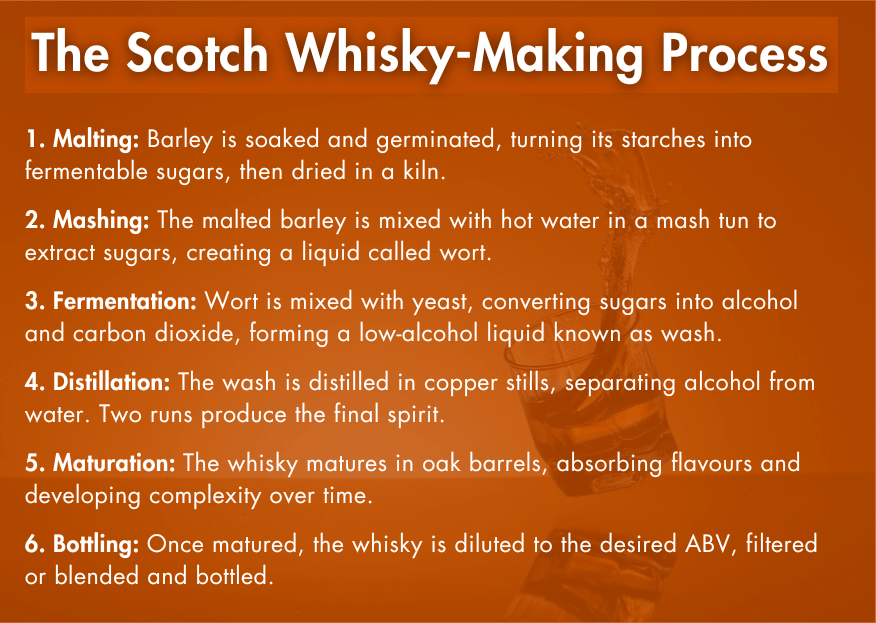

The process of Making whisky

In the process of whisky manufacture, necessary steps convert raw material into the flavourful drink we know today.

In the following paragraphs, I would like to cover the most critical points.

-

Malting. Before Scotch can be made, barley – Scotch's beloved malted grain – must be malted – or, put simply, germinated. That's because germinating converts starches in the barley into fermentable sugars. To germinate, the barley is soaked in water and then dried in a kiln for a day or two, which in turn turns the barley's starch into a chain of sugars. This chain unravels and allows enzymes within the barley to eventually act on it – and enzymes require a liquid environment to operate.

-

Mashing: The grist is added to water in a mash tun vessel, and the hot water helps to extract fermentable sugars from the barley to create a wort.

-

Fermentation: Wort is moved to fermentation vessels, where it is mixed with yeast. This inoculation converts the sugar in the wort into alcohol and carbon dioxide, creating a low-alcohol elixir called wash. Fermentation takes place over two to four days.

-

Distillation: The wash is then distilled in copper pot or column stills. In distillation, the wash is heated to the point that alcohol separates from the water and other impurities. Distillation generally consists of two runs. The first run is called the wash distillation. This produces low-proof liquid called 'low wines'. The next, or second, run produces the final high-proof spirit through an operation called "the spirit distillation".

-

Maturity: Whisky matures in oak barrels for years, drawing flavour from the wood. Over time, it transforms into a rich liquid, described chemically as an alcoholic solution of colour, flavour, and aroma compounds.

-

Bottling: If the Whisky has reached the necessary flavour profile, it is then ready to be bottled. This involves diluting the whisky to the required ABV with water and sealing the bottle. Some, but not all, whiskies will be filtered or blended and then bottled.

Throughout each stage of the process, careful craftsmanship and attention to detail are essential. From the malting of barley to the ageing of whisky in oak, every step is about creating the character and flavour of the whisky. Every single step.

Chat with us on WhatsApp

Chat with us on WhatsApp

Comments